In the world of fine wine there was a time when those with sophisticated palettes would harrumph and turn up their nose at the thought of sipping an American-produced wine. It was harshly referred to as drinking swill. It was thought that the climate, growingconditions, and grapes could not compare with what is found in France or other old world wine producing countries.

Then in 1976 at a prestigious wine competition, called the Judgment of Paris, a 1973 vintage Cabernet Sauvignon won first place among 10 top red wines in a blind taste test by leading French wine experts.

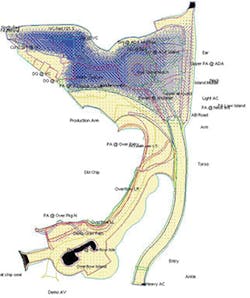

Google Earth image of the completed project

The winning variety was not only astoundingly good but it astounded the judges when they learned they had selected a wine produced in California, by Stag’s Leap Wine Cellars of Napa. Jaws dropped, eyebrows raised, and likely. . . “oh my gods,” were uttered (long before “OMG” became popular).

The result of the tasting has been described by Decanter magazine as “a victory that put California on the winemaking map, and established Stag’s Leap Wine Cellars as a global superstar.”

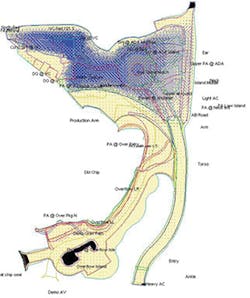

Keyway fill project

Since the astonishing win which was heard around the world, Stag’s Leap has continued to produce award-winning vintages and acquire other, neighboring vineyards. The winery has grown successfully.

Positioned seven miles north of Napa on the valley’s eastern side, Stag’s Leap Wine Cellars is located on a 240-acre estate with 90 acres of vineyards. Wine grapes have grown on this land continuously since the 1880s.

Suffice it to say Stag’s Leap has become a go-to destination for the wine elite and hoards of tourists. . .all wanting to see where some of the very best wine in the world is produced. To better accommodate guests, the winery needed a larger, multi-use facility for tastings, education, and business meetings.

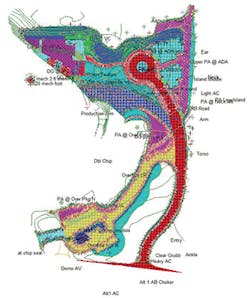

Cut/fill image and data

Winery management wanted a site for it’s new $7 million visitor facility that would awe visitors as much as they hope their wine does. The selected site is on the northeast corner of the estate and perched on the side of a hill. It provides vista views of the expansive rows of grape vines, the land, and the dramatic Stag’s Leap rock formation as a backdrop—in essence, a stunning view of the terroir. A vineyard is often characterized by its terroir, a French term loosely translating as “a sense of place” that refers to the specific geographical and geological characteristics of grapevine plantations, which help form the unique character of the wine.

Choosing the site for the new visitor center launched nine months of planning, engineering, and design required before site preparation could commence for a structure that would be built on a constructed ledge that essentially extended the hill that houses a network of man-made caves which have been used for years as cool temperature storage.

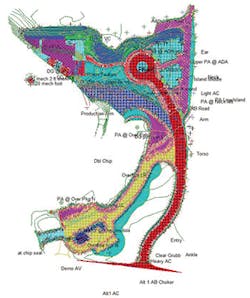

Cut/fill image and data

“This is a complicated and complex project,” states Bill Kopling, 3D modeler and takeoff technician with John Benward Company Inc., Sonoma, CA. “We knew that success on the project depends on accurate cost estimates based on detailed, digital plans for stripping, grubbing, cut and fill, and structural fill placement.”

Founded in 1979, John Benward Company is a Class A general engineering contractor firm providing all forms of site preparation for construction projects in the San Francisco North Bay Area—serving Sonoma, Napa, Northern Marin, and Solano Counties. A specialty area is wineries. The company has extensive experience and a notable reputation within the California wine industry.

For Benward Company, the project included site prep for a new visitors center, a roadway leading in, and two parking areas—one for 25 cars and an overflow area, which can accommodate two buses.

The big challenge was to extend the site plateau 125 feet (150 feet on the toe end) by adding 22,000 cubic yards of approved “select” fill with plasticity index of 15 or lower to meet the geotechnical requirements set by the project’s engineering firm. The building pad extension is adjacent to the network of man-made tunnels. On the site were 1,200 cubic yards of cave tailings from boring activities to create the cave network that remained when the caves were built.

To extend the site plateau and ensure fill stability for the new visitor center would require construction of a keyway at the base and a series of four benches measuring four-feet high by 12-feet wide for the length of the fill plateau.

Before construction could commence, Benward Company created a comprehensive bid estimate using the data points provided by Stag Leap’s contracted civil engineers.

“We used SiteWorks software from InSite to calculate exact take-off and fill quantities and utility quantities for the Stag’s Leap project,” says Kopling. “The software produces graphical construction layouts which helped us explain our cost estimates and provide visual imagery to help quantify the work necessary to create the project.”

During the planning and design phase of the project there were numerous changes and refinements to the construction plan. Benward Company was able to adjust quantities and its cost estimates each time with InSite SiteWorks earthwork and utility estimating software.

One time the winery’s design team made some major changes and Stag’s Leap management wanted to see updated costs for the next budget round due in a few days. Kopling states. “It was a lot of work and I literally had about

16 hours to produce everything to a very detailed level. Plus, I had a personal priority at the time—my wife was recovering from brain surgery. InSite SiteWorks is so powerful and easy to work with that I was able to do all the data input and modeling with her near my side, so I could address her convalescing needs. That wasn’t the best situation, but I’ve got to tell you that the software helped me pull a rabbit out of the hat that day.”

The software’s overlay feature accommodated updates to the subgrade and provided 3D views of the site as it developed.

“InSite SiteWorks software helped us win the job. It also helped Benward Company, the general contractor, and the Stag’s Leap facilities management considerably with its pre-construction planning and budgeting,” says Kopling. “A key benefit is that it helped us explore options that without it can be cumbersome and time consuming to complete.”

In looking back on the project, Kopling had this to say: “We’re proud to have helped Stag’s Leap Wine Cellars produce an absolutely stunning visitor center. They are truly good folks and deserve a facility as good as the wine they produce. And I’ll always remember how the InSite software helped us win the project and made it possible for me to be with my wife during a critical time. I know we’re supposed to keep our personal lives separate from the business, but there are exceptions . . . and in this instance my exceptional wife deserved my attention. This software allowed me to juggle several high priorities in my life without having to make a decision on only one. The portability of the software as well as a very understanding boss made this all possible.”